This post is a story about how we were approached with an opportunity to improve the safety of the work force at a large petrochemical refinery. The solution that was pitched was having the employees wear Cubs for personal PID protection and using a Tiger to locate a leak. With the number employees on site, there was need for a significant number of Cubs and Tigers. This is an example of how we can help educate people to create safer working environments for their employees.

Serval months ago, Ion Science were approached by a global producer of petrochemicals located in the middle east to see if we could provide a solution to address protecting their work force from exposure to the toxic industrial compounds produced on site.

An online meeting between Ion Science Portables and Personals team, the Senior Industrial Hygienist, Regional Manager, and local distributor concluded that the current product they were using was not sensitive enough for the industrial compounds that they were producing on site. They were using Lower Explosive Limit (LEL) detectors which have a pellistor inside them. A pellistor contains two beads, one bead ignites, and this increases the temperature. The temperature change is compared to an insulted bead. The difference tells you the percentage of combustible compound is in the volume. This is a destructive method of detection meaning a sample cannot be taken after measurement.

To begin with, they provided a breakdown of the compounds that can be found in the six areas of the refinery. Our Portables team worked to find all the detectable VOCs in this breakdown. For each detectable compound we used our Gas Table to find the OSHA and EH40 TWA values and the PID response factors. The customer had also specified an interest in the ACGIH TWA values. This is not a standard that is in our Gas Table. For this we purchased the ACGIH standards document and added them to the compound breakdown. Once these values had been collected, they were converted into Isobutylene equivalent ppm values. This allows you to directly compare the response of the TWA values and set one alarm to cover multiple gases (this will be covered in more detail below). By going through this breakdown, we showed them how versatile PID technology is at detecting a wide range of toxic compounds.

After this, we created an animation to show how readings on LEL sensors do not show the toxicity of the compounds in the breathing zone. Ethylene Oxide is a very toxic compound which has been linked to Lymphoma, Leukemia, Stomach and Breast cancer. The LEL of Ethylene Oxide is 3% of the volume. 10% on a LEL sensor for Ethylene Oxide is 0.3% of the volume. 1% volume is equal to 10,000 ppm. This means that 0.3% Ethylene Oxide is 0.3 X 10,000 = 3000 ppm. The legal limit for Ethylene Oxide over an 8-hour period is 1 ppm. 10% LEL is 3000 times higher than the TWA. The LEL sensor is not sensitive enough to protect against Ethylene Oxide exposure. You can find the link to the animation at the end of the post.

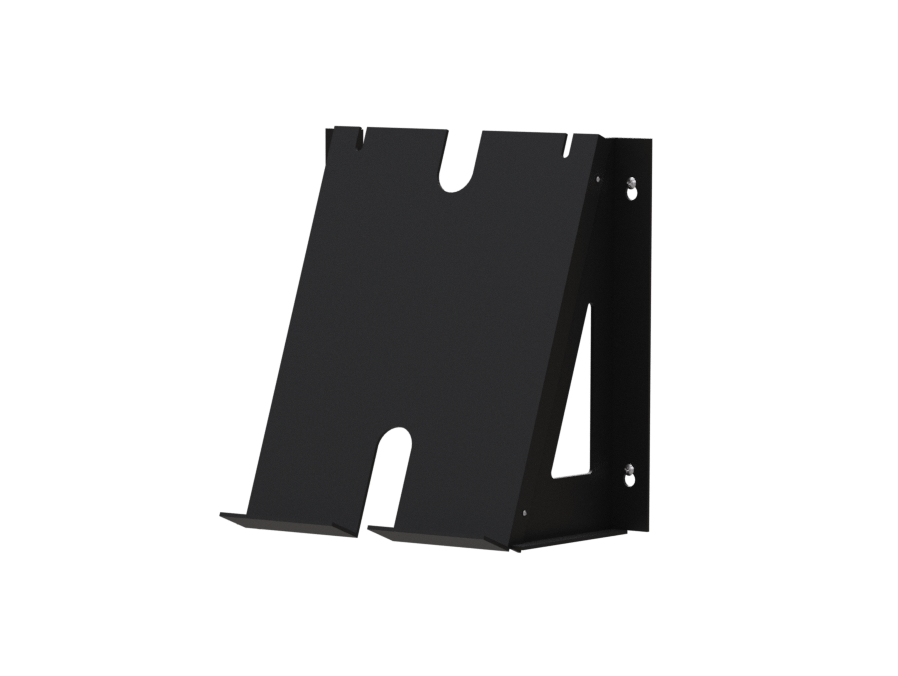

To accompany the video, a presentation was created to add more information on the how PID and the Isobutylene equivalent method could improve their employee safety. This is a more detailed description of how the Isobutylene equivalent method is implemented. If you have 10 compounds in an area, you can divide the 10 TWA values for those compounds by their Response Factors. This will give you the TWA values for those 10 compounds if the instrument was set to Isobutylene. We call this the Isobutylene equivalent TWA. If 7 of the 10 compounds had Isobutylene equivalent TWAs which were above 20 ppm. When you set the alarm to 20 ppm the instrument would alarm for 70% of the compounds in that area. This protects the employees in that area from 70% of these compounds. If the Cub was to go into alarm, then a Tiger could be used to locate the exact source of the leak. PID is a nondestructive method of detection so a Tedlar bag could be connected to the exhaust of the Tiger to take a sample taken which can be sent to a lab for analysis. If you would like to see this presentation, please email Technical Support and we will be happy to send that to you.

This information was given to the Industrial Hygienist for their pitch to secure funding. This pitch was successful, and we are currently in the process of agreeing exact numbers of Cubs and Tigers. These are ways that we are happy to work with you to educate people and show them the importance and the ability of PID technology. If you find yourself in a situation like this, please do talk to us here at ION Science and if you have your own story like this to tell please write a post of your own.

Leave A Comment

You must be logged in to post a comment.